Serie MVD V8M

Gama Industrial

MVD V8M Series

Under certain conditions, the new V8M series allows the connection of up to 200% of the outdoor unit capacity

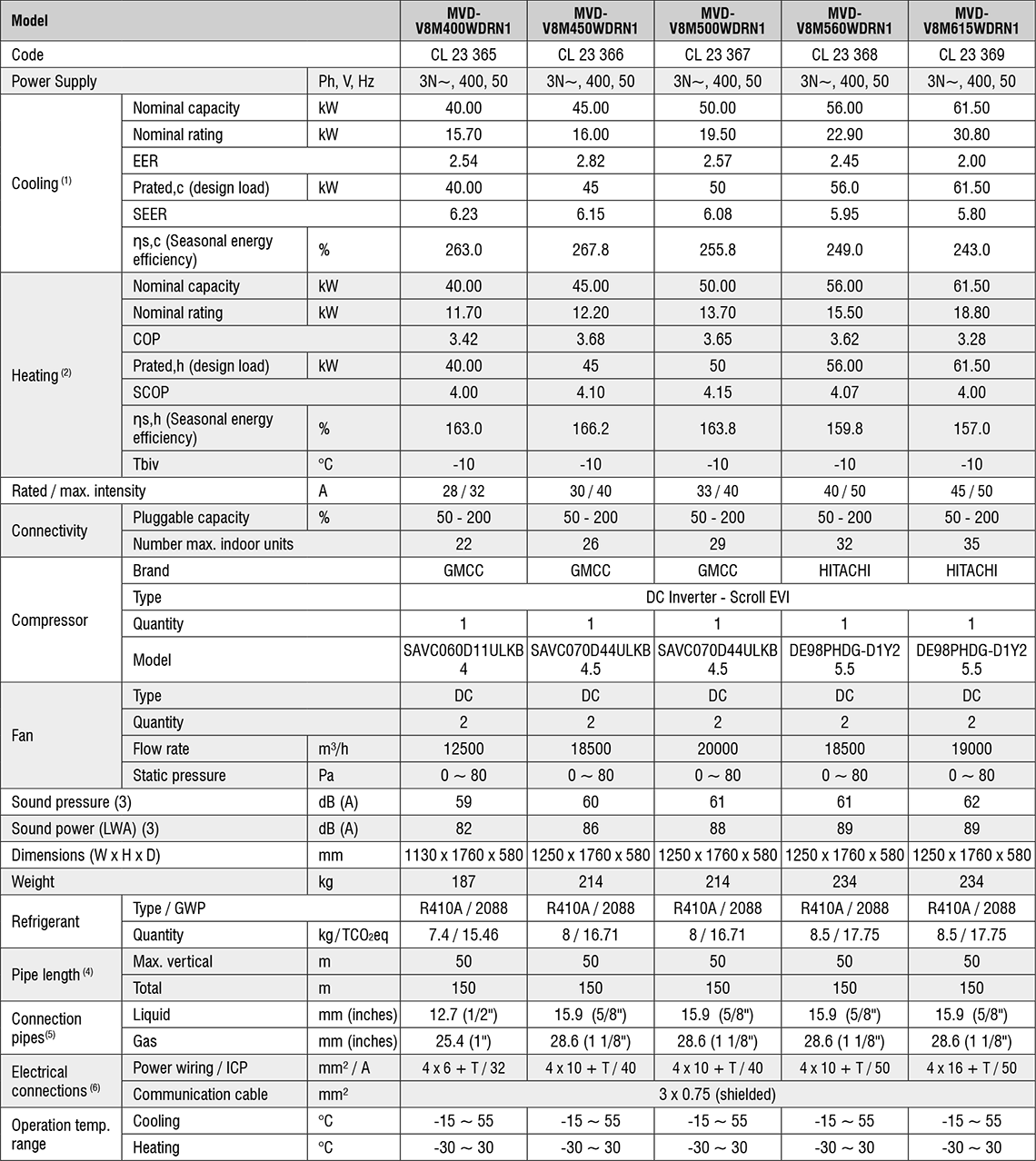

Technical specifications

Note:

(1) Nominal cooling conditions: indoor 27 °C DB, 19 °C WB and outdoor 35 °C DB, for a pipe length of 5 m and a height difference of 0 m. (2) Nominal heating conditions: indoor 20 °C DB, 15 °C WB and outdoor 7 °C DB, for a pipe length of 5 m and a height difference of 0 m. (3) Pressure noise level measured in a semi-anechoic chamber at 1 m frontal distance and 1.3 m height. (4) Pipe length when outdoor unit is installed higher than the indoor units. (5)The specified diameters are for the service valves, this does not mean that the pipe must have this diameter. (6) Power wiring recommended for L < 20 m, for longer distances it should be recalculated.

* Data measured under EUROVENT EN 14825 conditions, at 100% simultaneity.

** All the data and specifications can be changed without previous notice